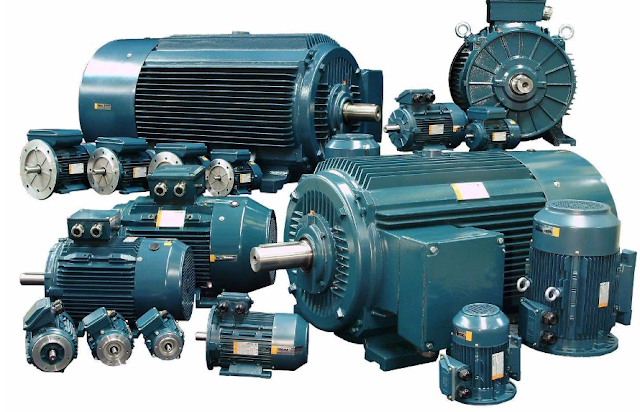

Product Description

68series shaded Pole Motor

Motor Description:

1.Our motors performance(data) are per customers` requirments.

2.Motor wires are cooper and some could be used aluminium wire to save cost

3.Motors could be used ball bearing and oil bear(Sleeve bearing) both.

4.Insulation Class B/F

withstand voltage:1800V/S/0.5mA

Rotation:CW (view from the shaft side)

Noise<50dB

Interturn Isulation:>2100V

Isulation Resistance:20MΩ

IP:34

Life span:>2000Hours (continuous working).Normal use:10 years

Operation Temperature/Humidity Range:-40°C to +65°C, 0%~95%

5.Safe,reliable, low noise, high performance,characteristics hard, good and stable starting, long life, etc.

6.Typical Application: Exhaust fan, air purifier, micro-oven, fan, induction cooker, refrigerator, pump, heater, hood oven, blwer, air conditioner, Heater machines, dehumidifiers

7.Motor Specification as below chart

| MODEL | A OF SIZE | SHAFT DIA | VOLT | POWER | TORQUE | SPEED RATED |

| YJ6820C | 20MM | 5MM | 110-240V | 60W | 68.66mN.m | 3000RPM |

| YJ6822C | 22MM | 5MM | 110-240V | 60W | 86.30mN.m | 3000RPM |

| YJ6825C | 25MM | 5MM | 110-240V | 65W | 102.63mN.m | 3000RPM |

| YJ6828C | 28MM | 5MM | 110-240V | 80W | 99.10mN.m | 3000RPM |

| YJ6830C | 30MM | 5MM | 110-240V | 80W | 96.71mN.m | 3000RPM |

| YJ6833C | 33MM | 5MM | 110-240V | 90W | 93.68mN.m | 3000RPM |

| YJ6840C | 40MM | 5MM | 110-240V | 100W | 134.69mN.m | 3000RPM |

| YJ6850C | 50MM | 5MM | 110-240V | 110W | 189.60mN.m | 3000RPM |

Fine Watt motor focus on offering motor solutions to smart products for home appliance ,like BLDC,Capacitor motor,shaded pole motor,universal motor and mini generator. Our motors are widely used in kitchen,air conditional,Ice chest,washing machine,etc. Customers locate not only in China domestic ,also oversea from Asia to European and Amecica. Our engineer with 20 years experience in motor design and development,win a lot of motor inovation technology award,Our engineer also provide technical support to other big facotry.we believe we always can find the best solution for your product.

Company FAQ

(1) Q: What kind motors you can provide?

A:For now,we mainly provide Kitchen Hood Motor,DC Motor,Gear Motor,Fan Motor Refrigerator Motor,Hair Dryer Motor Blender Motor Mixer Motor,

BLDC Motor,Shade Pole Motor,Capacitor Motor, PMDC Motor,Synchronous Motor,etc

(2) Q: Is it possible to visit your factory

A: Sure. We always like to meet our customer face to face,this is better for understanding.But please kindly keep us posted a few days in advance so we can make good arrangement.

(3) Q: Can I get some samples

A: It depends. If only a few samples for personal use or replacement, I am afraid it will be difficult for us to provide, because all of our motors are custom made and no stock available if there is no further needs. If just sample testing before the official order and our MOQ, price and other terms are acceptable, we will provide samples.

(4) Q: Is there a MOQ for your motors?

A: Yes. The MOQ is between 1000~10,000pcs for different models after sample approval.

But it’s also okay for us to accept smaller lots like a few dozens, hundreds or thousands

For the initial 3 orders after sample approval.For samples, there is no MOQ requirement. But the less the better (like no more than 5pcs) on condition that the quantity is enough in case any changes needed after initial testing.

(5)Q: What advantage do you have?

A: For motors, we have quality guarantee, if there is probelm motor after inspection in customer house,we will replace .

For service, we offer 24 hours technical support and barrier-free communication with excellent service people.

Technical service: Except offer actual motor products,we can also offer motor technical supporting seperately to our customer.Our engineers are represent the most advanced techonogy.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Universal |

|---|---|

| Speed: | Low Speed |

| Number of Stator: | Single-Phase |

| Samples: |

US$ 5/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can you explain the advantages of using a 3-phase motor?

Using a 3-phase motor offers several advantages over other types of motors. Here’s a detailed explanation of the advantages of using a 3-phase motor:

- High Efficiency: 3-phase motors are known for their high efficiency. They can convert electrical energy into mechanical energy with minimal losses. The balanced three-phase power supply and the design of the motor result in a smoother and more efficient operation compared to single-phase motors.

- Power Factor: 3-phase motors have a better power factor compared to single-phase motors. Power factor is a measure of how effectively the motor utilizes the electrical power. By having a higher power factor, 3-phase motors reduce the amount of reactive power required from the power supply, resulting in improved overall power system efficiency.

- High Starting Torque: 3-phase motors can provide high starting torque, making them suitable for applications that require the motor to start under load. The three-phase power supply and the design of the motor enable it to produce a strong rotating magnetic field, which allows for efficient starting and acceleration of the motor’s rotor.

- Smooth Operation: The rotating magnetic field produced by the three-phase power supply results in smooth and continuous operation of the motor. This characteristic makes 3-phase motors ideal for applications that require constant and reliable operation, such as industrial machinery, pumps, compressors, and HVAC systems.

- Compact Size and Weight: 3-phase motors tend to be more compact and lightweight compared to equivalent power single-phase motors. This compactness is due to the even distribution of the windings around the stator and the absence of additional starting components often required in single-phase motors.

- Higher Power Output: 3-phase motors can deliver higher power output compared to single-phase motors of similar size. The balanced three-phase power supply and the design of the motor allow for efficient utilization of electrical power, enabling the motor to provide greater mechanical power output.

- Lower Maintenance: 3-phase motors generally require lower maintenance compared to other types of motors. The balanced three-phase power supply and the absence of starting components, such as capacitors or centrifugal switches, reduce wear and tear, resulting in longer motor life and reduced maintenance requirements.

- Wide Availability and Standardization: 3-phase motors are widely available and standardized, making them easily accessible for various applications. They are manufactured in a wide range of sizes and power ratings, allowing for flexibility in selecting the appropriate motor for specific requirements.

Overall, the advantages of using a 3-phase motor include high efficiency, better power factor, high starting torque, smooth operation, compact size and weight, higher power output, lower maintenance requirements, and wide availability. These advantages make 3-phase motors suitable for a wide range of applications in industrial, commercial, and residential settings.

What factors should be considered when selecting a 3-phase motor for an application?

When selecting a 3-phase motor for a specific application, several factors need to be considered to ensure optimal performance and compatibility. Here’s a detailed explanation of the key factors to consider:

- Power Requirements: The power requirements of the application should be carefully evaluated. Determine the required horsepower (HP) or kilowatt (kW) rating of the motor based on the load characteristics, such as the torque and speed requirements. Consider both the continuous power requirements and any intermittent or peak power demands that the motor may experience during operation.

- Voltage and Frequency: Verify the available voltage and frequency of the power supply in the application. Ensure that the motor’s voltage and frequency ratings match the power supply to ensure compatibility and safe operation. Common voltage ratings for 3-phase motors include 208V, 230V, 460V, and 575V, while frequencies are typically 50Hz or 60Hz.

- Motor Speed: Determine the required speed of the motor for the application. Depending on the specific requirements, you may need a motor with a fixed speed, multiple speed options, or variable speed capabilities. Consider the motor’s synchronous speed, which is determined by the number of poles and the power supply frequency, and ensure it aligns with the desired operating speed.

- Motor Enclosure: The motor enclosure should be selected based on the environmental conditions in which the motor will operate. Consider factors such as temperature, humidity, dust, corrosive substances, and the presence of flammable or explosive materials. Common motor enclosures include open drip-proof (ODP), totally enclosed fan-cooled (TEFC), and explosion-proof enclosures.

- Efficiency: Energy efficiency is an important consideration to minimize operating costs and environmental impact. Look for motors that meet or exceed applicable efficiency standards, such as the NEMA Premium efficiency standards in the United States or the IE efficiency classes defined by the International Electrotechnical Commission (IEC).

- Motor Size and Mounting: Consider the physical size and mounting requirements of the motor, ensuring it fits within the available space and can be securely mounted. Check the motor’s frame size, which indicates the physical dimensions and mounting compatibility, such as NEMA frame sizes in the United States or IEC frame sizes internationally.

- Starting Method: Evaluate the starting requirements of the application. Depending on the load characteristics and the power supply capacity, you may need a motor with specific starting methods, such as direct-on-line (DOL) starting, reduced voltage starting (e.g., star-delta or autotransformer starting), or electronic soft starters. Consider the starting torque and current requirements to ensure successful motor startup.

- Overload Protection: Determine the type of overload protection required for the motor. Overload protection devices, such as thermal overload relays or electronic motor protection relays, help prevent motor damage due to excessive heat or current overload. Select an appropriate overload protection device based on the motor’s power rating and the specific application requirements.

- Reliability and Serviceability: Consider the reliability and serviceability aspects of the motor. Look for motors from reputable manufacturers with a track record of producing reliable products. Evaluate the availability of spare parts, technical support, and service centers for maintenance and repairs. Additionally, consider factors such as motor lifespan, bearing design, and ease of access for maintenance tasks.

- Compliance and Certifications: Ensure that the selected motor complies with relevant industry standards and certifications, such as NEMA, IEC, UL (Underwriters Laboratories), CSA (Canadian Standards Association), or specific industry requirements. Compliance with these standards ensures that the motor meets safety, performance, and quality standards.

Considering these factors when selecting a 3-phase motor helps ensure that the motor is well-suited for the application, delivers optimal performance, and operates reliably and efficiently over its lifespan.

What role do 3-phase motors play in the efficiency of HVAC systems?

3-phase motors play a crucial role in enhancing the efficiency of HVAC (Heating, Ventilation, and Air Conditioning) systems. Here’s a detailed explanation of their contribution:

- Air Handling Units (AHUs):

- 3-phase motors are commonly used in HVAC systems to power the fans in air handling units (AHUs). These fans circulate and distribute conditioned air throughout the building.

- The use of 3-phase motors in AHUs allows for efficient and reliable operation. They can deliver the necessary airflow at varying static pressures, ensuring optimal air distribution and ventilation in different zones of the building.

- Chillers and Cooling Towers:

- In large-scale HVAC systems, 3-phase motors are utilized in chillers and cooling towers. These components are responsible for cooling the water used in the HVAC system.

- Efficient 3-phase motors drive the compressors and fans in chillers and cooling towers, enabling effective heat transfer and temperature control. This results in improved energy efficiency and cooling performance of the HVAC system.

- Variable Air Volume (VAV) Systems:

- 3-phase motors are often employed in Variable Air Volume (VAV) systems, which allow for individual control of airflow in different zones or rooms of a building.

- By using 3-phase motors in VAV systems, the air volume can be easily adjusted to meet the specific cooling or heating demands of each zone. This enables precise temperature control, reduces energy wastage, and enhances overall HVAC system efficiency.

- Energy-Saving Measures:

- 3-phase motors in HVAC systems can be integrated with energy-saving measures to improve efficiency. For example, they can be paired with variable frequency drives (VFDs), which allow for the modulation of motor speed and power consumption based on actual needs.

- VFDs control the speed of 3-phase motors, ensuring that they operate at optimal speeds for different load conditions. This results in significant energy savings, as motors consume less power when operating at lower speeds.

- Reliability and Durability:

- HVAC systems require reliable and durable components to ensure continuous operation. 3-phase motors are known for their robust construction and ability to withstand the demanding conditions typically found in HVAC applications.

- The reliability of 3-phase motors minimizes the risk of motor failures and unexpected downtime, allowing HVAC systems to operate efficiently and maintain occupant comfort.

Overall, 3-phase motors play a critical role in enhancing the efficiency of HVAC systems. They power the fans, compressors, and pumps, enabling effective air distribution, temperature control, and heat transfer. Their integration with energy-saving measures further optimizes energy consumption, resulting in improved overall HVAC system efficiency and reduced operating costs.

editor by CX 2024-04-09