3 Phaseac Motor

We will work together to accelerate the realization of your goals and create the best quality motor products. Our service staff and technical support will be online 7 * 24 hours contact us3-Phase AC Motors

Three-phase alternating current electric motors typically provide higher efficiency, greater operating economy, and more operating versatility than single phase motors. Three-phase motors are used in situations requiring low power/on demand start, controlled acceleration, adjustable operational speed, controlled starting current, and adjustable torque limit. They typically serve a variety of applications and are used by factories, HVAC, farmers, and manufacturers, to name a few. Our offerings differ by horsepower, voltage, RPM, frame and motor enclosure design. Also, be sure to check out our complete line of general purpose AC motors, three–phase motors, DC motors, farm duty motors and motor supplies.

Three Phase Motor

An induction motor or 3 phase induction motor is an AC electric motor in which the electric current in the rotor needed to produce torque is obtained by electromagnetic induction from the magnetic field of the stator winding

Three Phase Synchronous Motor

The operation of the three-phase synchronous motor can be summarized as follows:Three-phase AC voltage is applied to the stator windings and a rotating magnetic field is certainly produced.

DC voltage is applied to the rotor winding and a second magnetic field is certainly produced.

3 Phase Synchronous Motor

Synchronous motors are not self-starting and therefore require a method of bringing the rotor up to near synchro nous speed before the rotor DC power is applied. Synchronous motors typically start as a normal squirrel cage induction motor through use of special rotor amortisseur windings.

3 Phase Induction Motor

The polyphase induction motor invented by Nikola Tesla in 1886 had been developed by 1895 virtually into its present squirrel-cage form. The slip-ring induction motor was developed a short time later. Because of its simplicity and cheapness, the 3-phase squirrel-cage induction motor is now by far the most common type of motor in use for driving industrial plant, particularly of small power ratings (up to 20 kW).

3 Phase Ac Motor

If you are wondering about the difference between 3 phase vs single phase AC motors, just remember this. Single phase AC motors usually operate on a single phase source of power while 3 phase AC motors operate on a three phase source of power. The single phase alternating current is the most common source of power used by most households and non industrial businesses. It is the power that is used to light homes and power TVs in North America.

3 Phase Electric Motor

Three-phase motors are more efficient than single phase motors and are commonly found in applications requiring more than 7.5 horsepower. Although the National Electric Code does not specify specific conductor colors for three-phase current, it is common to use black, red and blue wires to identify lines L1, L2 and L3 respectively. The voltage cycle of each line lags its predecessor by 120 degrees — L2 reaches its peak voltage after L1, and L3 reaches its peak voltage after L2. Two wiring configurations, Wye and Delta, indicate the wiring methods for three-phase motors.

Our Mission & Vision

At ZH, our vision and mission is to help design and produce the best quality products and build a first-class international brand

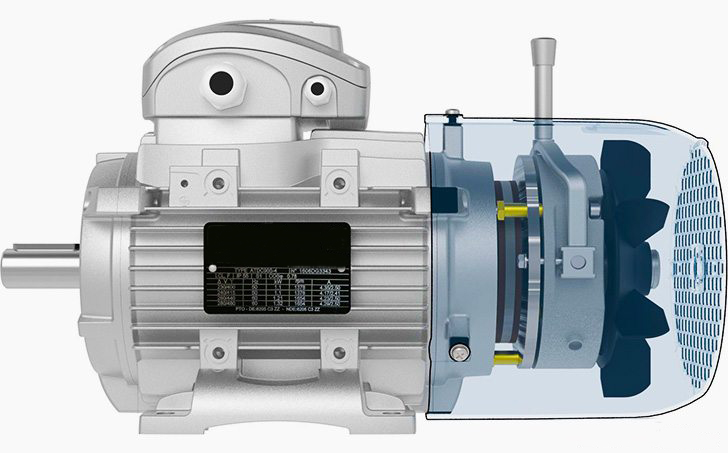

which is most commonly used with variable voltage variable frequency (VVVF) converters. These motors are used to drive drive pumps, fans, compressors, mixers, agitators, mills, conveyors, crushers, machine tools, and cranes. The reliability of squirrel cage AC induction motors, compared to DC motors, is high. The AC induction motor comprises 2 electromagnetic parts, stator, and rotor. AC induction motors should be designed or selected to match the load requirements of any particular application. The most common type of AC motor is the totally enclosed fan cooled (TEFC) motor, which is provided with an external forced cooling fan mounted on the non-drive end (NDE) of the shaft, with cooling ribs running axially along the outer surface of the motor frame. Direct-on-line (DOL) starting is the simplest and most economical method of starting an AC squirrel cage induction motor. The selection of the motor is dictated by the type of load and the environment in which it operates.

Latest Message

Via Galilei, Rome, Lazio, Italy

October 29, 2001: Established here

How It Works

To actually achieve torque at the motor shaft, a current is applied across the stator. This creates a rotating magnetic field which in turn induces a current in the rotor. Because of this induced current, the rotor also creates a magnetic field and starts to follow the stator due to magnetic attraction. The rotor will turn slower than the stator field, and this is referred to as ‘slip.’ If the rotor were to turn at the same speed as the stator, no current would be induced, thus no torque. The difference in speed ranges from 0.5-5% depending on the motor winding.

Churge Blog

The Latest News & Updates

China Standard 75kw Three Phase Motor Explosion Proof AC Electrical Asynchronous Induction Ye2 Series vacuum pump diy

China factory CE ISO9001 Chinese Motor Factory Approved Single Phase Induction Motor AC Motor Electric Motor (YC YL YY MY ML) vacuum pump booster

China supplier AC Three Phase Asynchronous Electric Motor vacuum pump diy

HZ-MOTOR and its affiliates are distributors of mechanical power transmission components including AC motors. For more information about the brands and/or prices we offer, please contact us by phone 353-469-7653, email [email protected], or fill out our online contact form.